Little Known Facts About Premier Aluminum Llc.

Table of ContentsWhat Does Premier Aluminum Llc Do?Premier Aluminum Llc - QuestionsThe Single Strategy To Use For Premier Aluminum LlcNot known Details About Premier Aluminum Llc

(https://devpost.com/garymartin53403?ref_content=user-portfolio&ref_feature=portfolio&ref_medium=global-nav)Using low price and unqualified vendors can create quality issues, and squandered time and money in the long run. To assist you with the process, below are some things to think about when picking the ideal steel spreading supplier.

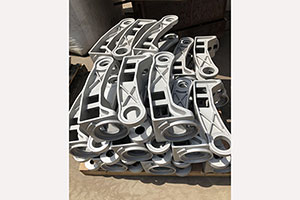

A company that just utilizes the investment spreading procedure will attempt to offer you on why that process is best for your application (Aluminum Casting company). What if utilizing the sand spreading process is best for you and your requirements? Instead, search for a vendor that supplies a series of casting processes so the very best option for YOU is selected

If dealing with a solitary source for all of your spreading requires is very important to you, the distributor requires to be varied in its capacities. When combined with other incorporated capacities, this can help simplify and compress the supply base. When choosing the appropriate casting vendor, mindful consideration should be provided to top quality, solution, and price.

Our Premier Aluminum Llc Statements

Customers significantly select spreading providers that have machining abilities. If the spreading supplier finds a concern during machining, the problem is fixed quicker with no disagreement over whose fault it is.

Problem or no, integrated machining simplifies the supply chain and reduces his response dealing with time and shipping cost before the item makes it to the consumer. What do you need from your casting vendor? Are you trying to find somebody to simply provide a metal part to your front door or do you need a lot more? As an example, if you do not have internal metallurgy knowledge, validate that the supplier can supply support in selecting the appropriate alloy based on your details application - Foundries in Wisconsin.

Some factories are limited or specialized. Make sure the distributor can satisfy all your material or alloy demands to remove the demand for multiple suppliers.

The Buzz on Premier Aluminum Llc

Study the distributor's website. Talk to a sales rep or service affiliate.

Light weight aluminum is likewise light-weight and has great corrosion resistance, making it suitable for applications where weight and sturdiness are important elements. Furthermore, light weight aluminum spreading is a cost-effective technique of production, as it needs much less energy and sources than other methods. Iron casting, on the other hand, entails pouring molten iron right into a mold to develop a preferred form.

Unknown Facts About Premier Aluminum Llc

Iron spreading is additionally able to endure high temperatures, making it ideal for usage in applications such as engine parts and commercial machinery. Iron casting can be much more expensive than light weight aluminum spreading due to the higher cost of raw products and the energy called for to melt the iron. When deciding in between aluminum casting and iron casting, it is necessary to take into consideration the specific requirements of the application.

In final thought, both aluminum casting and iron casting have their very own one-of-a-kind benefits and downsides. There are three sub-processes that drop under the group of die casting: gravity die spreading (or irreversible mold casting), low-pressure die casting and high-pressure die spreading. To get to the completed product, there are three primary alloys used as die spreading material to choose from: zinc, aluminum and magnesium.