Understanding the Relevance of Foam Control in Industrial Processes

In industrial processes, foam control is frequently an ignored yet crucial element that directly influences operational efficiency and product integrity. The presence of extreme foam can bring about considerable difficulties, including disrupted blending and lessened response kinetics, which may eventually affect item top quality across various sectors such as drugs and food manufacturing. Comprehending the nuances of foam management, consisting of reliable methods and potential improvements, increases vital concerns about ideal methods and future innovations. What are the effects for industries pursuing improved productivity and conformity?

The Function of Foam in Industry

Foam plays a substantial function in various commercial processes, affecting both effectiveness and item high quality. In industries such as food and drink, pharmaceuticals, and petrochemicals, foam can offer both damaging and advantageous objectives. In the food sector, foam stabilization is important throughout processes like whipping lotion or producing beer, where the high quality of foam straight impacts customer assumption and product attributes.

In chemical production, foam can serve as a barrier, preventing the appropriate blending of reagents, which can lead to suboptimal yields and incomplete responses. Alternatively, in processes like flotation in mineral handling, foam is used to divide valuable minerals from waste material, improving recuperation prices.

Furthermore, in wastewater treatment, foam development can show the presence of raw material, offering as an essential specification for procedure surveillance. The ability to manage foam is crucial for maintaining process security and maximizing functional costs. Understanding the function of foam in commercial applications permits operators and engineers to apply effective foam management techniques, making certain that foam adds favorably to total process performance while reducing its prospective disadvantages.

Typical Difficulties of Foam Development

Several sectors encounter substantial obstacles because of the unexpected development of foam throughout numerous processes. Foam can interrupt the efficiency of operations, leading to raised downtime and greater operational expenses. In sectors such as pharmaceuticals, food and drink, and wastewater therapy, foam can impede mixing, reduce item yield, and complicate separation procedures.

In addition, foam can produce safety and security threats by obstructing clear visibility, which is crucial in environments where specific measurements and monitoring are essential. The existence of foam can also bring about devices damage, as too much stress buildup might happen in reactors and containers.

Furthermore, the need for constant intervention to take care of foam can divert sources and labor, eventually affecting efficiency. Environmental guidelines position an additional difficulty, as too much foam can lead to non-compliance concerns in effluent discharge, requiring added treatment procedures.

Impact on Item Quality

In chemical manufacturing, foam can prevent reaction kinetics by restricting gas-liquid call, leading to incomplete responses and reduced yields. This not just impacts the performance of manufacturing however can additionally result in low quality end items that do not satisfy governing requirements or client specs.

In addition, in drugs, foam development during formula procedures can present air bubbles right into delicate compounds, compromising medication effectiveness and security. Furthermore, foam can cause operational issues such as overflow and devices malfunctions, boosting downtime and upkeep prices, better impacting product quality and consistency.

Strategies for Effective Foam Control

Attending to the obstacles positioned by foam is essential for preserving item high quality across numerous commercial markets. Reliable foam control approaches are necessary to minimize the damaging results of foam development, which can disrupt procedures and compromise item stability.

One of the primary Foam Control methods includes the choice and application of proper antifoaming agents. These agents are developed to decrease surface stress and hinder bubble development, and their efficiency can vary based upon the details procedure conditions. Regular surveillance of foam degrees is vital to ensure prompt treatment, enabling operators to use antifoaming agents prior to foam ends up being a significant concern.

Furthermore, optimizing process parameters such as temperature and agitation can play a crucial duty in foam administration. Decreasing frustration intensity or changing feed rates can lessen foam generation. Implementing mechanical foam control tools, such as foam breakers or defoamers, can likewise provide efficient services for high-foaming applications.

Educating personnel on foam monitoring techniques and the value of preserving optimum operating conditions further improves foam control initiatives. Foam Control. By utilizing a mix of these techniques, sectors can successfully take care of foam, making sure functional effectiveness and keeping the quality of their items

Future Fads in Foam Management

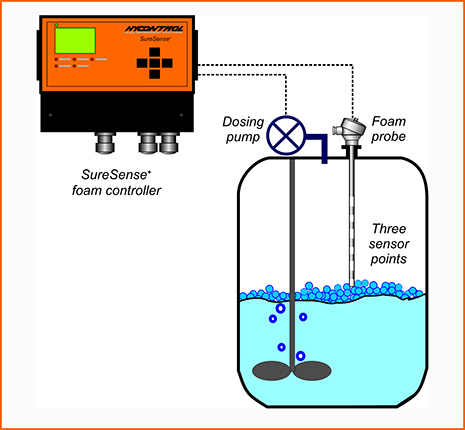

How will improvements in modern technology shape the future of foam management in industrial procedures? The assimilation of expert system (AI) and maker understanding will certainly revolutionize foam control techniques, enabling real-time tracking and flexible feedbacks to foam development. These modern technologies can analyze operational specifications and historical data to anticipate foam habits, enabling preemptive procedures that enhance procedure efficiency.

Furthermore, the advancement of sophisticated foam control agents, including bio-based and eco-friendly options, is acquiring traction. These developments not only mitigate foam but also straighten with sustainability objectives, lowering the environmental footprint of industrial operations.

Automation will certainly additionally play an essential duty, as automated foam control systems can maximize the dosage of defoamers based on real-time measurements, decreasing waste and boosting efficiency.

Additionally, the adoption of IoT (Internet of Things) tools will certainly assist in seamless communication in between tools and foam control systems, making certain an all natural technique to foam management. (Foam Control)

Conclusion

To conclude, reliable foam control is essential for maximizing industrial processes throughout different sectors. The challenges postured by foam formation can dramatically impact item quality and functional performance. Carrying out critical foam management techniques, consisting of using antifoaming representatives and process optimization, minimizes these difficulties. As markets remain to progress, ongoing innovations in foam control innovations will certainly even more improve productivity and sustainability, making sure conformity with environmental laws while maintaining the stability of items.

In the food industry, foam stabilization is critical throughout processes like whipping cream or creating beer, where the top quality of foam straight impacts consumer understanding and item features.

Recognizing the role of foam in industrial applications i loved this allows drivers and designers to implement effective foam administration methods, making certain that foam adds about his favorably to total procedure efficiency while minimizing its potential drawbacks.

Regular monitoring of foam levels is essential to guarantee prompt intervention, permitting drivers to use antifoaming representatives prior to foam comes to be a substantial concern.

Applying mechanical foam control tools, such as foam breakers or defoamers, can additionally give reliable options for high-foaming applications.

The combination of man-made intelligence (AI) and machine learning will reinvent foam control approaches, making it possible for real-time surveillance and flexible reactions to foam formation.